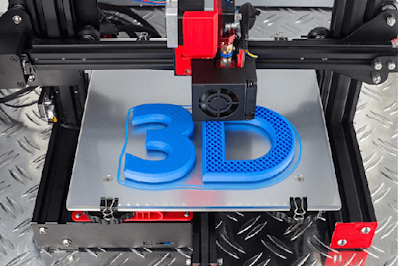

3D printing in the world of bearings

3D printing, also known as additive manufacturing, has been altering various industries for some years now. The technology has been highly praised for its ability to fabricate complex and customized designs, reduce lead times and production costs, and shorten supply chains. One industry that has greatly benefitted from 3D printing is the bearing industry. Bearings, which are essential components of most mechanical systems, continue to play a crucial role in ensuring optimal operation and functionality of equipment. The traditional process of manufacturing bearings is predominantly subtractive , meaning that parts are removed from a raw material to create a final product. However, 3D printing offers an alternative to this method by allowing manufacturers to build a bearing design layer by layer, making prototyping faster, cheaper, and more efficient than traditional techniques. 3D printing has opened up new possibilities and opportunities for bearing engineers, manufacturers and u